inventory

As with the Linea Mini, this kit expands the range of functions of the Linea Micra. With the help of a needle valve and the corresponding paddle mechanism, it is possible to define a set flow rate for the pre-infusion and activate it via the paddle. The valve is located directly in front of the brewing boiler/brewing group, so that changes in the flow rate have an immediate impact. The conversion converts the “fake paddle” into a fully-fledged paddle.

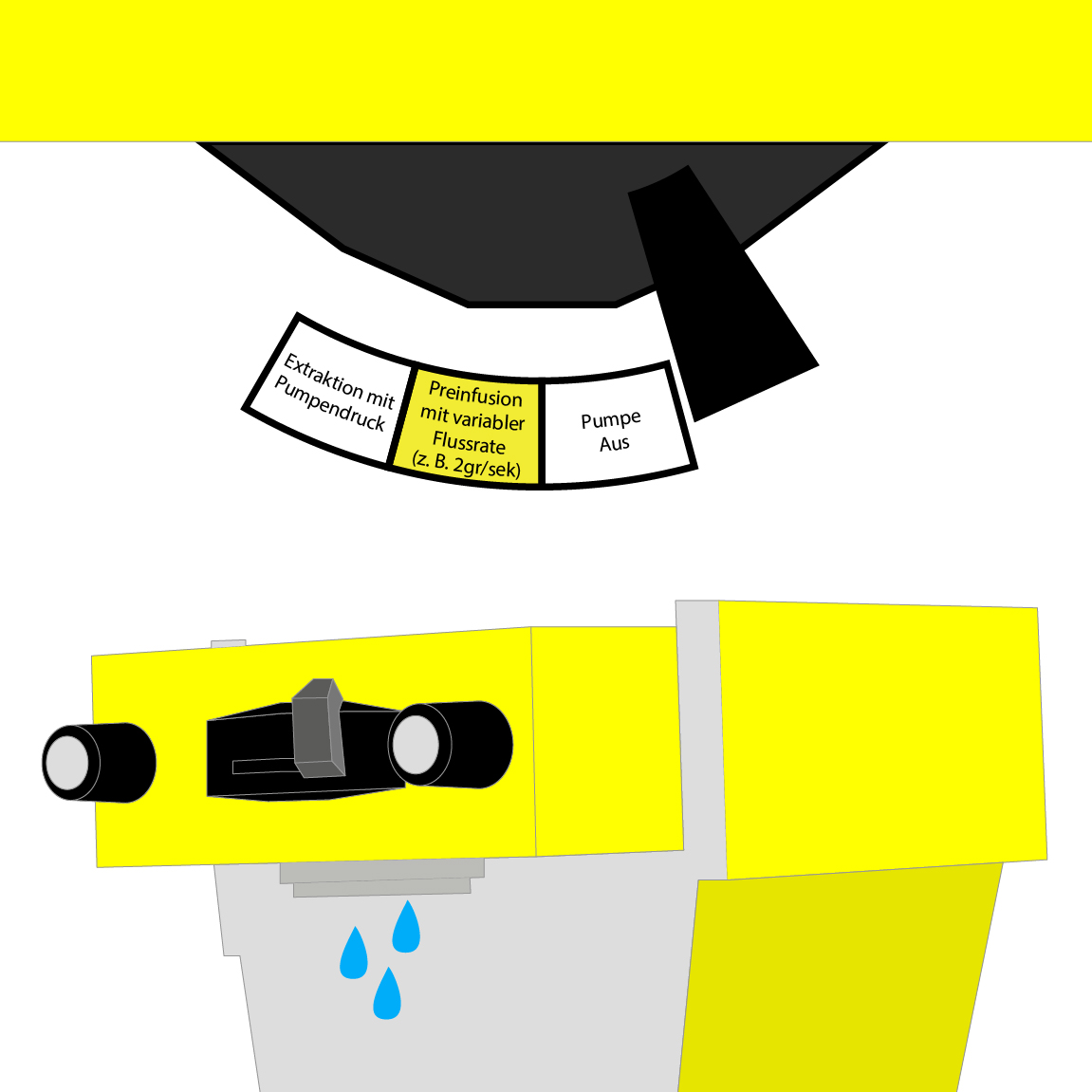

The pre-infusion position is in the middle position. There the water must flow through the needle valve so that the flow rate is reduced to the set value. Both the duration of the pre-infusion and the flow rate can be freely selected.

Following the pre-infusion, the paddle is pushed further to the left. The valve switches and the regular flow rate and pump pressure act on the puck.

Video Linea Micra with needle valve

What advantages does the conversion have?

Due to the low flow rate during pre-infusion, we achieve that the puck is saturated slowly and with almost no effect of the pump pressure. This is comparable to the so-called blooming of filter coffee. This makes the extraction more consistent and reduces the susceptibility to channeling. The conversion also allows us to adjust two additional variables. The flow rate and duration. For example, we can grind finer if we extend the duration of the pre-infusion. The big advantage of the two-stage system is reproducibility. Once you have found the right settings for a variety, you can easily reproduce the covers.

What to pay attention to?

The Linea Micra's switchable steam boiler is a great way to reduce the machine's power consumption. Please note the following: The flow rate of the needle valve changes depending on the temperature. So if the machine is set to a flow rate with the steam boiler switched on and fully heated up, the flow rate will differ slightly when operating without the steam boiler and with a short heat-up time. In my series of measurements, I achieved reproducible results both with and without the steam boiler switched on. When the steam boiler was deactivated, the flow rate reduced from 1.5 grams/second to 1.2 grams/second.

When operating with a water tank, I noticed slight downward swings after filling (probably due to air bubbles in the system). It also appears that the pump also has slightly different delivery rates at different temperatures inside the machine. (Keyword bypass on the pump head).

What is included in the kit?

- fully assembled wiring harness

- all required hydraulic components and fittings

- sufficient Teflon hose

- 3d printed paddle mechanism

- detailed assembly instructions

What is needed to carry out the conversion?

The conversion can be carried out very easily by anyone. I like to compare it to building a shelf. You need some time, desire and the right tools. If you carry out all the steps in the right order, that's half the battle.

Required tools & material

- a set of screwdrivers

- a set of open-end wrenches

- Liquid sealant for sealing hydraulic components.

- If necessary, an electrician for the electrical connection of the wiring harness if you are not familiar with the subject.

How long does installation take?

The time required to simply assemble the kit is 2 to 3 hours for an experienced screwdriver. Inexperienced mechanics should plan on an afternoon. Added to this is the drying time of each liquid sealant.

What do I do if I don't get anywhere despite detailed instructions?

So far everyone has been able to complete the conversion successfully. If you have any questions, I am available via email.

There are no reviews yet.